In daily use of wet dust collector some common problems and solutions, wet dust collector is to make the dust gas and liquid close contact, with

the inertial collision of water droplets and particles, or the full mixing of water and dust and other functions to capture particles or make particles increase or stay in fixed containers to achieve the separation effect of water and dust.

1. The temperature of dusty gas is too high, and the system does not adopt any thermal insulation measures, so that the temperature difference between the dust in the pipeline and dust collector and the external environment is large, and the water vapor

precipitated in the heat exchange process condenses, which increases the humidity and viscosity of dust, so thermal insulation measures should be taken.

2. The parameters of pulse injection system are not set properly, and the dust removal effect

of shipyard dust collector is poor. The power plant dust remover is a dry dust filter. It is suitable for collecting fine, dry and non fibrous dust. The filter bag is made of textile filter cloth or non-woven felt, and the filtering effect of fiber fabric

is used to filter the dust containing gas. When the dust containing gas enters the bag filter, the dust with large particle and large proportion will settle down due to gravity and fall into the ash hopper. When the gas containing fine dust passes through

the filter material, the dust is retained and the gas is purified. For example, the time interval of pulse injection of filter bag is too long, the width of pulse injection is too short, and the pressure of compressed air is too low, resulting in the

decrease of filter bag tension and the accumulation of dust on the filter bag is too thick. The relevant parameters of pulse injection system should be reset.

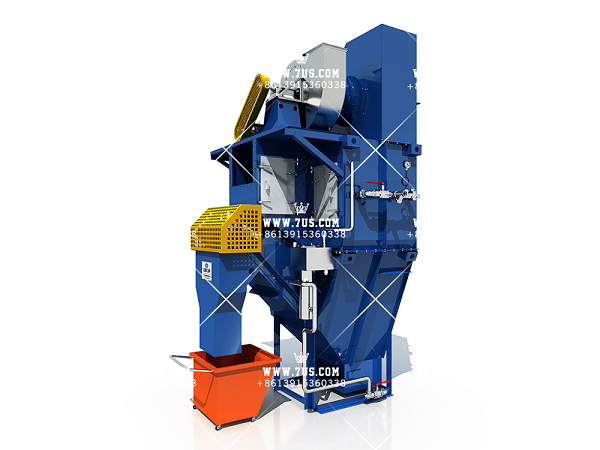

Use wet dust collector

3. Filter bag material and dust characteristics do not match,

resulting in part of the pores blocked. Bag filter is a dry dust filter. It is suitable for collecting fine, dry and non fibrous dust. The filter bag is made of textile filter cloth or non-woven felt, and the filtering effect of fiber fabric is used to

filter the dust containing gas. When the dust containing gas enters the bag filter, the dust with large particle and large proportion will settle down due to gravity and fall into the ash hopper. When the gas containing fine dust passes through the filter

material, the dust is retained and the gas is purified. For the dust with high concentration, small particle size, high humidity and viscosity, membrane filter material should be selected.

4. If the dust concentration treated by the system is too

high and the filtering air speed of the filter material is too high, the pressure difference of the filter bag will be too high. The dust removal load of bag filter and the filtration wind speed of filter material should be reduced appropriately, that

is, increase the filtering area and reduce the filtration wind speed of filter material.

6. Regularly check the wear of the filter bag, and handle the broken bag in time. The small hole can be glued and mended, and the large one should be replaced.

The quality of the dust remover of the dust remover manufacturer not only directly affects the reliable operation of the charging water tank, but also relates to the normal operation of the production system, the environmental sanitation of the workshop

area and the surrounding residents, the wear and life of the fan blades, and also involves the recycling and utilization of economically valuable materials.

More information about wet dust collector, do in the second ring environmental protection.

After decades of technical precipitation and continuous innovation,

Jiangsu Erhuan Environmental Protection

Technology Co., Ltd. has an elite team of R & D, design and production. The company has successfully developed slant insert filter cartridge dust collector and vertical ultra-high efficiency filter cartridge dust remover by introducing the

fine production process of European and American dust collectors.