Oct 29, 2020

Fume dust collector, as its name implies, is a dust removal equipment for processing flue gas dust. Different dusts have different effects on the design and operation of dust removal equipment. The performance of the dust collector is expressed by the volume of the process gas and the resistance loss of the equipment.

Fume dust collectors are widely used in concrete mixing plants, dust control in major mines, dust control in workshops, and dust control at points where grinding and cutting dust are generated.

1. Dust is a small solid molecule suspended in the air. When the solvent evaporates and the solute condenses, such as paint dust produced by paint operations. The solid particles formed by mechanical impact, grinding and rolling of solid materials are dispersed by airflow and suspended in the air, which is called dust. Its particle size is about 0.25-20 microns, most of which are 0.5-5 microns.

2. Smoke is unburned particles produced by materials (feed, wood, oil, coal, etc.), or black smoke produced by residual unburned ash is usually called smoke. Its particle size is very fine, even less than 0.5 microns.

3. Smoke and dust are solid particles produced by physical and chemical processes called soot. For example, dust particles formed by sublimation and condensation during smelting, burning and metal welding. Most of its particle size is relatively fine, generally less than 1.0 microns.

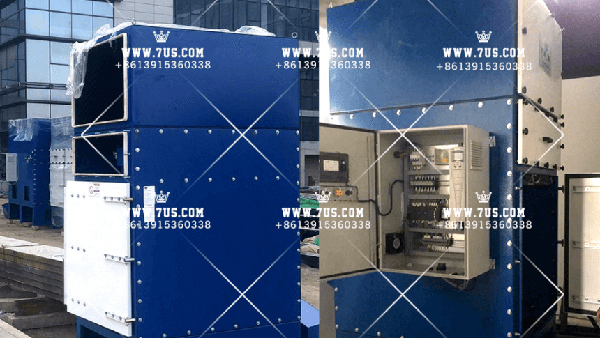

If you want information about removing the duster, it's all in the Erhuan. After decades of technological precipitation and continuous innovation, Jiangsu Erhuan Environmental Technology Co., Ltd. now has an elite team of R&D, design and production. The company has introduced excellent dust collector production technology from Europe and the United States, and currently has many products such as Cartridge dust collector, Wet dust collector and Baghouse dust collector.