Sink flow filter cartridge dust collector is a kind of high efficiency and energy-saving dust collector. A new type of high-efficiency

pulse dust collector based on bag filter is developed, which combines the advantages of various chamber back blowing dust collectors, overcomes the shortcomings of insufficient cleaning intensity and uneven distribution of inlet and outlet air, and

expands the application scope. Next, we will introduce the working principle of the filter cartridge dust collector.

Cartridge filter cartridge dust collector is equipped with air inlet, bag, framework, air outlet, air bag, pulse controller, injection valve, injection pipe, etc. When the dust containing gas enters the dust collector from the air inlet, the velocity

of the air flow slows down, and the coarse particles separate from the air flow and settle into the dust collecting room. When the fine dust passes through the bag with the airflow, it is blocked on the outer surface of the bag, and the clean gas is discharged

from the air outlet; When the dust layer on the surface of the bag is thick, the pulse controller sends a command to open the injection valve, and the compressed air in the air bag is ejected at a high speed through the jet pipe. At the same time, the

surrounding air which is several times the amount of air injected is induced to enter the bag and eject rapidly from the inside to the outside. The dust on the outer surface of the bag is blown down into the dust collecting chamber and discharged by the

ash hopper. The way of pulse injection is adopted in the dust removal of the dust collector, which not only can clean the dust thoroughly, but also does not damage the filter cartridge, so that the service life of the filter cartridge can be guaranteed.

The cleaning process is automatically controlled by pulse controller, which can be controlled by pressure difference or time.

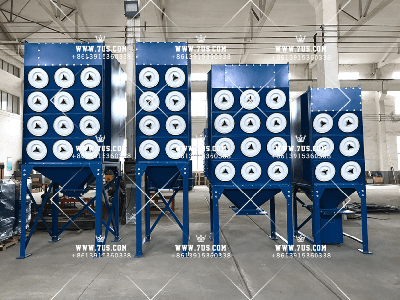

Sink flow cartridge dust collector

For more information about the cartridge dust collector, do in the second ring

environmental protection. After decades of technical precipitation and continuous innovation,

Jiangsu Erhuan Environmental Protection Technology Co., Ltd.

has an elite team of R & D, design and production. The company has successfully developed slant insert filter cartridge dust collector and vertical ultra-high efficiency filter cartridge dust remover by introducing the fine production process

of European and American dust collectors.