Many customers do not know how to install the pulse bag filter after purchasing it. In fact, the second ring environmental protection company provides the installation service of pulse bag filter. In order to understand some precautions in the installation process, Jiangsu second ring environmental protection listed the following contents for you to learn.

1. It is recommended to press the sealing strip or packing and glass glue on the flange of the upper box and ash hopper (ash bin) of the pulse bag dust collector, so as to prevent the fine dust from escaping from the gap

2. It is better to fix the

pulse bag filter and the ground with anchor bolts. It is better to lay the foundation or cement surface on the ground to ensure that the position is flat and not inclined.

3. Generally, the ladder and guardrail are welded on the box body. When installing,

make sure that the sparks will not run into the box. If you are not sure, in order to pull out the dust removal bag, after the ladder and guardrail are installed, the bag should be filled to prevent the spark from entering the box and burning the bag.

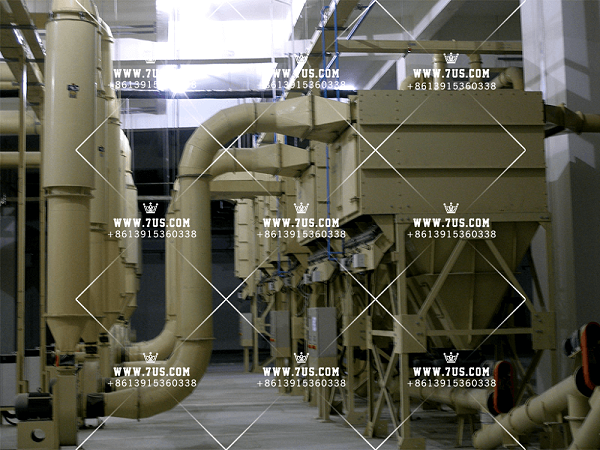

Pulse bag filter

4. Before starting and using pulse bag filter, make sure that the air pump has been ventilated, and then turn off the air pump after the fan and equipment are shut down

5. The ash in the ash hopper (ash bin) should be cleaned

regularly. Don't wait until the ash is full, so as not to affect the effect

6. The pressure of air supply to the equipment does not need to be too high. The working pressure of pulse valve is 4 kg, and the air pump is 0.6-0.9 cubic meters

7. The air inlet and outlet of pipeline and equipment shall be connected tightly

More information about bag filter is available in the second ring road. After decades of technical precipitation and continuous innovation,

Jiangsu Erhuan Environmental Protection Technology Co., Ltd. has an elite team of R & D, design and production. The company has

successfully developed slant insert filter cartridge dust collector and vertical ultra-high efficiency filter cartridge dust remover by introducing the fine production process of European and American dust collectors.