3D Printing Dust Collector

-

-

1.1.3D printing dust collector, air volume range: 1000-100000CMH.

1.2.The ultrafine particles of flammable and explosive dust and metal dust (such as magnesium, aluminum, titanium, aluminum alloys, etc.) used in metal 3D printers.

1.3.After printing, it is necessary to clean the excess powder inside the 3D printer and on the workpiece, as this type of powder material poses a risk of fire or explosion.

1.4.The printing equipment and supporting dust removal system operate under argon protection, and it is necessary to ensure that the working chamber is in an oxygen free environment to ensure maximum safety.

1.5.In addition, long-term contact and inhalation of powder particles by the human body can also pose certain health risks, so timely cleaning is necessary.

-

-

1.6. Therefore, it is necessary to equip with dust removal equipment to timely remove and filter the smoke and dust generated by burning, ensuring high-quality printing while improving the safety and reliability of the metal additive manufacturing process.

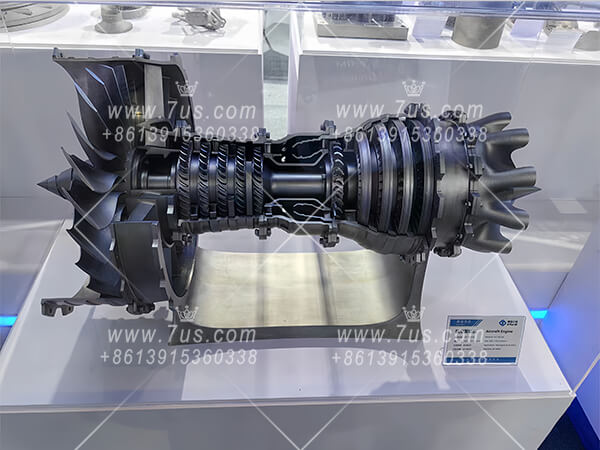

1.7. The metal 3D printing equipment is equipped with a dust removal system for the forming room. The dust removal system adopts a primary cyclone dust collector and a secondary filter cartridge dust collector.

1.8. The dry dust removal system requires any explosion prevention and control measures such as venting, inerting, and suppression.

1.9. Dry dust collectors are usually used, but wet dust collectors can also be used. Aluminum, magnesium, and titanium metals will produce hydrogen when they come into contact with water. Wet dust collectors need to be equipped with hydrogen

safety release valves.

Application Cases

-

3D printing-cartridge type dust collector

-

3D printing-cartridge type dust collector

-

3D printing-wet type dust collector

-

3D printing-wet type dust collector

-

3D printing-wet type dust collector

-

3D printing-wet type dust collector

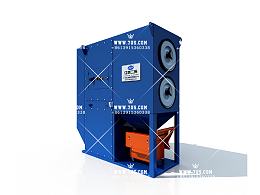

Downflow all -in-one dust collector

Downflow all -in-one dust collector  3D printing dust collector

3D printing dust collector