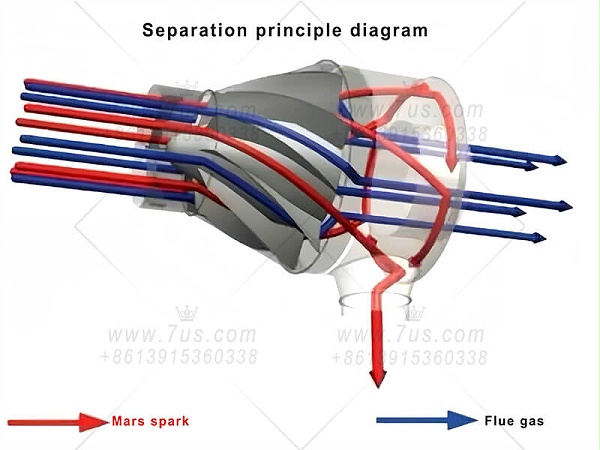

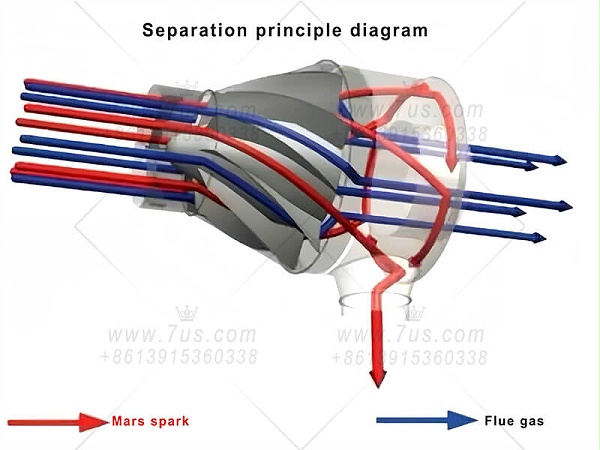

Mars Spark Arrestor-Swirl Collision typePrevent bag filter cartridges from catching fire

-

-

1.1.The swirl type is not only used in laser cutting, robot continuous welding, but also generates a large amount of splashing sparks during metal cutting and polishing.

1.2. It is also used for extinguishing sparks generated by high-temperature casting, steelmaking, smelting intermediate frequency furnaces, and biomass boilers. Depending on the concentration, a star shaped discharge valve is required to discharge

the ash.

1.3. When a large amount of continuous splashing sparks are generated, they will directly enter the dust collector along with the exhaust duct of the dust collector.

1.4.The dust collector is equipped with filter material, and when encountering a large number of continuous sparks on the surface, it often causes a fire accident.

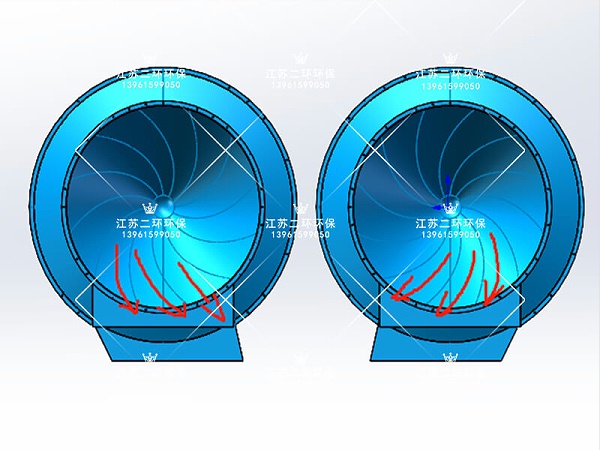

-

-

1.5. Even if flame retardant filter materials are used, a large amount of sparks can also burn the surface of the filter materials, causing dust leakage in the dust collector and filtration failure.

1.6. The filter material is the heart of the dust collector. Once it fails and leaks powder, it is scrapped and needs to be replaced with a new filter material, causing serious economic losses.

1.7. The Mars catcher is customized according to the diameter of the pipeline, and the inlet and outlet dimensions of the fire catcher are consistent with the diameter of the pipeline, making installation simple and convenient.

1.8. Through specialized software simulation, precise dimensions and angles of the cross-section are obtained to arrange air ducts and form a cyclone with consistent direction, resulting in very good results.

Industry applications

spark catcher

spark catcher  Mars Spark Arrestor-Swirl Collision type

Mars Spark Arrestor-Swirl Collision type