Plasma cutting machine dust collector

-

-

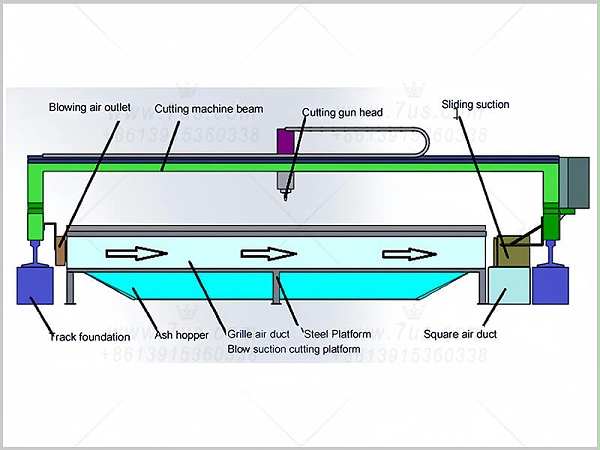

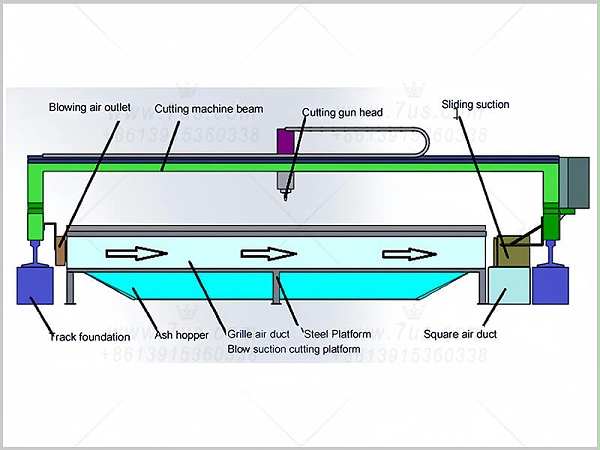

1.1.Plasma cutting machine dust collector, air volume range: 1000-100000CMH.

1.2.Plasma cutting machines are used to cut thick plates, and the concentration of smoke and dust generated during cutting is relatively high.

1.3.When renovating, it is necessary to install an exhaust duct type slide rail for the travel of the cutting machine, and new cutting machines usually have exhaust ducts already installed at the factory.

1.4.When cutting, the exhaust port corresponding to the bottom slide rail opens to remove the smoke and dust generated by the cutting.

1.5.At the same time as the air outlet is opened, a small fan is usually installed opposite the air outlet to blow and suck simultaneously, achieving good dust removal effect.

-

-

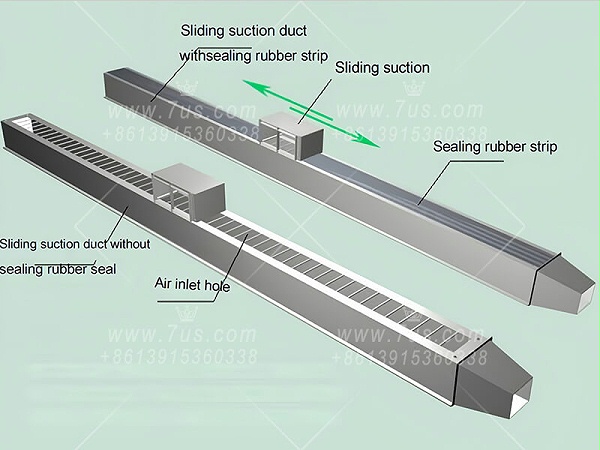

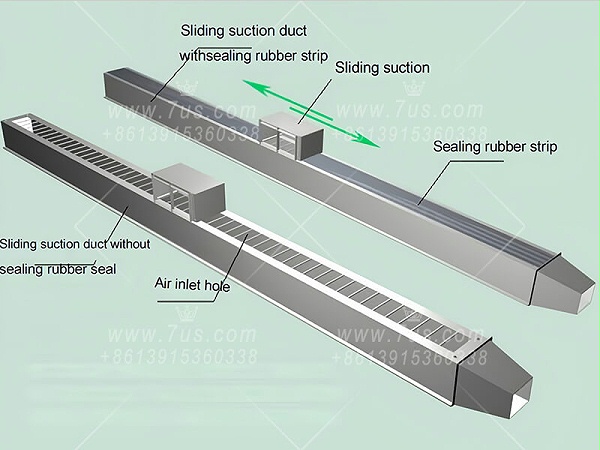

1.6. This sliding suction duct is used for smoke exhaust and dust removal systems where the suction port moves randomly. It moves synchronously with the travel of the cutting head, and wherever it cuts, it is sucked in.

1.7. It mainly relies on the negative pressure of the fan to attach the sealing rubber strip to the upper surface of the sliding air duct opening for sealing, and the position of the sliding suction port can be used for air intake.

1.8. Conventional large-scale dust collectors can be used, including dry filter cartridge dust collectors or wet dust collectors.

1.9. Design Services: Free of charge to design product drawings according to the appropriate size of your on-site space,and provide installation guidance and training services

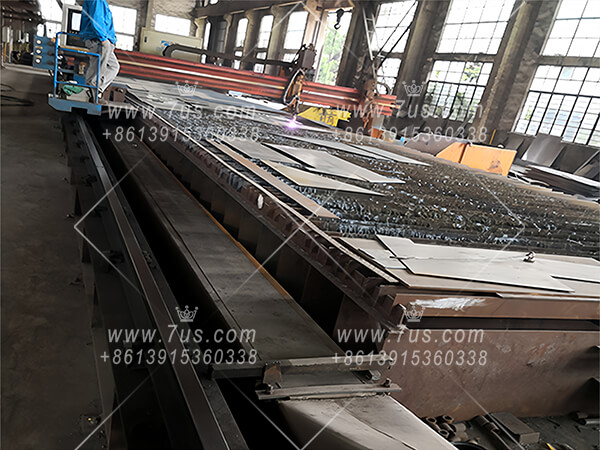

Application Cases

-

3D printing-cartridge type dust collector

-

3D printing-cartridge type dust collector

-

3D printing-wet type dust collector

-

3D printing-wet type dust collector

-

3D printing-wet type dust collector

-

3D printing-wet type dust collector

Vertical modular combination dust collector

Vertical modular combination dust collector  Vertical all -in-one dust collector

Vertical all -in-one dust collector