1、Mixture of centrifugal fan and dust collector

2、Dynamic settlement and water mixture with wave tumbling

3、water consumption low

4、continuous running

5、air volume constant

6、The collected dust is discharged in the form of mud

RCN-C type wet dust collector (with zipper mud scraper)

RCN-C type wet dust collector (with zipper mud scraper)

RCN-C type wet dust collector (with zipper mud scraper)

RCN-C type wet dust collector (with zipper mud scraper)

with zipper mud scraper+activated carbon filtration

with zipper mud scraper+activated carbon filtration

with zipper mud scraper+activated carbon filtration

with zipper mud scraper+activated carbon filtration

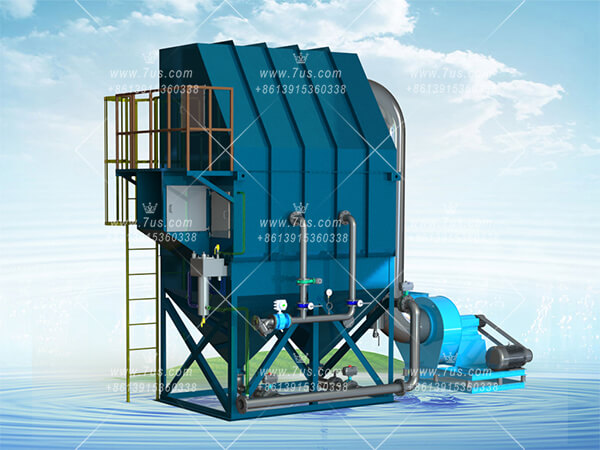

RCN-D type wet dust collector

RCN-D type wet dust collector

RCN-D type wet dust collector

RCN-D type wet dust collector

LV type integrated machine

LV type integrated machine

LV type integrated machine

LV type integrated machine

RCN-B Type wet dust collector

RCN-B Type wet dust collector

IOM Type Wet grinding and dust removal workbench

IOM Type Wet grinding and dust removal workbench

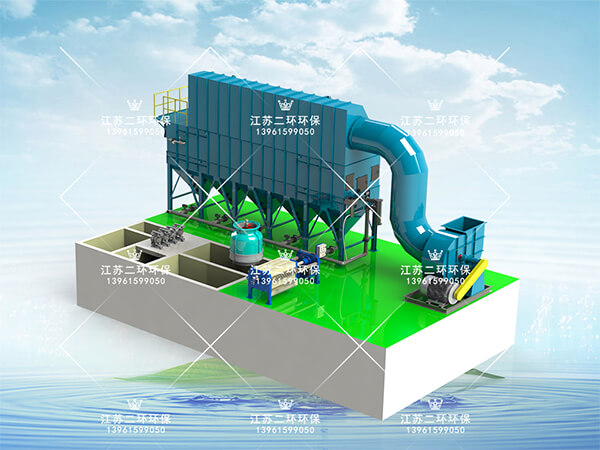

Dust removal process of sintering machine, mixer, and slag trap in steel vanadium steelmaking plant

Dust removal process of sintering machine, mixer, and slag trap in steel vanadium steelmaking plant

Wet dust removal process for ore crushing, rod grinding, and magnetic separation

Wet dust removal process for ore crushing, rod grinding, and magnetic separation

Wet dust collector for ore crushing

Wet dust collector for ore crushing

Wet dust collector for crushing machine

Wet dust collector for crushing machine

Al,Mg,Ti ATEX Flammable and explosive metal dust

Al,Mg,Ti ATEX Flammable and explosive metal dust

Wet dust collector+F9+HEPA

Wet dust collector+F9+HEPA

A: Sure. For high temperature water vapor dust mixture flue gas generated in production processes such as sintering machine, mixer, slag trap, suspension magnetization roasting, etc. in steel vanadium steelmaking plants, it has a good dust removal effect. After purification, the emission concentration of general particulate matter is ≤ 10 mg/m3 or less.

2. Can the flammable and explosive fine powder produced by processing aluminum, magnesium, and titanium alloys be used?A: Sure. When polishing and polishing aluminum magnesium titanium alloy, the fine powder generated belongs to flammable and explosive dust. The self-excited wet dust collector does not need a water pump or a spray head, and is not afraid of clogging! It has a good effect on explosion-proof and dust removal. In response to the problem of some metal powders dissolving in water to generate hydrogen, the structure of the self-excited dust collector has a hydrogen export channel. When the unit stops, the hydrogen discharge valve on the top of the equipment is in a normally open state.

A: Sure. The casting release agent is usually formulated with cork powder, bone glue, waste oil, etc. The micropores of filter materials such as cloth bag filter cartridges are easily blocked, resulting in paste bag paste. Therefore, dry filter material dust collectors are not suitable for this working condition, and the use of self-excited dust collectors is an ideal choice.

4. Is the water consumption of wet dust collectors large?A: The water consumption is not large because it is recycled. When a portion of water is lost by evaporation, and the liquid level switch senses it, it will open the electromagnetic valve to automatically replenish water. The liquid level control is divided into three sections: high, medium, and low, which are sequentially displayed on the touch screen. It can make corresponding decisions and perform action linkage in combination with the PLC program.

A: Of course it can be used. For example, the equipment is installed in an indoor environment above zero degrees Celsius; Install a steam heating device in the water tank; Install an electric heating wire heating device in the water tank; Electric heat tracing and insulation devices are wound outside the water tank, etc; Are effective anti freezing measures.

6. When using a wet dust collector, how to handle sewage discharge?A: If there is a sewage station, it can be directly discharged to the sewage station for treatment. If there is no sewage station, sludge separation devices such as filter presses and magnetic separators are selected for sludge water separation to obtain relatively dry sludge recovery, and the clarified liquid is recycled by the system.

A: The wet dust collector is equipped with an automatic floating object collector, which uses the overflow method to retrieve the suspended objects from the inside of the machine.

8. How large can the air volume be? Is the pressure loss large?A: The air volume range of the wet dust collector is currently between 10000 and 500000 cubic meters per hour. The pressure loss consumed by the machine itself is between 1500-2000Pa, so the wind pressure for fan selection is basically above 3000Pa.

A: The self-excited wet dust collector does not require water pumps, spray heads, or fillers, and is not afraid of clogging. Based on the principles of aerodynamics, it designs special air flow channels, utilizes the pressure head of the fan, turbocharges, blows up continuously rolling and overturning waves, and creates waves to wash smoke and dust. Unlike the simple process of water spray tower and throat venturi wet type, it is as simple as casually installing a water pump, adding some filler, and atomizing and spraying through a nozzle. The soul of self-excited type lies in accurate airflow stop area design and precise liquid level control; Otherwise, the spray cannot be turned over, the effect cannot be achieved, and the dust removal will fail. The impact type or impact type dust collector is a domestic imitation of some of the functions of the American RCN self-excited dust collector.

10. Does the wet dust collector need to be shut down for sludge discharge?Answer: The self-excited wet dust collector can of course operate continuously for 7 * 24 hours and discharge sludge online. During equipment maintenance, it is only necessary to shut down the machine to empty the water tank and discharge mud.

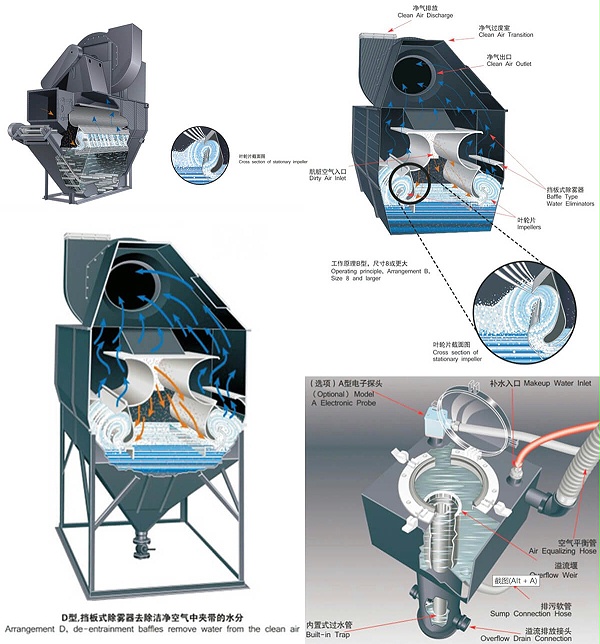

The N-type wet dust collector utilizes the centrifugal force of a fan to fully mix water and dust containing gas, and then discharge clean air. When dust laden air flows through a stationary impeller partially submerged in water, a water curtain is generated, and dust is removed as it passes through this water curtain, quickly forming a turbulent water curtain through the air flow through the impeller. At the bottom of the blade, there is a carefully designed slot to supplement additional water to the narrower opening of the impeller blade. The upward rolling water through the slot increases the interaction between dust and water, thereby increasing the efficiency of dust collection. The centrifugal force generated by the rapid change in the direction of the air flow causes the dust to be stably captured as it passes through the water curtain.

The moisture carried in the clean air is removed by carefully designed wide space "V" shaped mist removal baffles (for small sizes) or 3 curved baffles (for larger sizes). The water in the sink is recycled repeatedly. After the water curtain generated by air flow is formed, no water pump or nozzle spray is required. A small amount of clean water is always added to the water replenishment joint to supplement the water taken away during evaporation or sludge removal.

Type C wet dust collector can reduce manual slag removal. This type of slag removal method is more suitable for situations where medium or high concentration dust containing gases require 24-hour continuous operation, or where manual slag removal is not feasible. Type C automatic slag removal is often used for gas emission in casting sand transportation, sandblasting, polishing, grinding, material transportation, desiccant, or processing conditions. The side wall of the sink bucket is steep, reducing material accumulation, and the slag remover can automatically clean up the collected sludge. The slag remover is driven by a small power gear motor and is suitable for continuous operation. Sprockets and chains are made of materials that can withstand prolonged friction. The rotational speed of the chain is low, about 2 feet per minute (about 0.6 m/min), and the steep conveyor belt enables sludge to be dehydrated during discharge. The cleaning water is retained, reducing the amount of make-up water.

D type valve controls scouring and slag removalThe D-type wet dust collector controls the discharge of sludge through the opening and closing of valves at the bottom of the water tank bucket, and the sludge is transported to the discharge treatment point through a pipeline system. It can be continuously washed or intermittently washed. This type of slag removal method is suitable for material transportation in chemical or quarrying industries, dust removal by pulverizers, screening, mining or quarrying transfer points, etc. In order to stabilize the water level in the dust collector, continuous water replenishment and drainage are necessary.

steamWashing machine, garbage disposal

device, die-casting machine, cutting device, paint spray, welding, freezer, EDM machine tool, paint removal device, electroplating, lead smelting device, galvanizing device, ingot casting device

steamWashing machine, garbage disposal

device, die-casting machine, cutting device, paint spray, welding, freezer, EDM machine tool, paint removal device, electroplating, lead smelting device, galvanizing device, ingot casting device

smogWelding, laser processing, melting

furnace, engine test bench, cutting machine, quenching workshop, die casting, holding furnace, foundry, baking and glass melting process, incineration device, fire prevention device

smogWelding, laser processing, melting

furnace, engine test bench, cutting machine, quenching workshop, die casting, holding furnace, foundry, baking and glass melting process, incineration device, fire prevention device

Al Mg Ti alloy dust Minimal

lubrication, spray production, machining, deburring, and electric brushes. Cutting, grinding, subsequent process, forging

Al Mg Ti alloy dust Minimal

lubrication, spray production, machining, deburring, and electric brushes. Cutting, grinding, subsequent process, forging

Al Mg Ti alloy Drilling,

milling, rough milling, sawing, deburring, molding process, waste recycling technology

Al Mg Ti alloy Drilling,

milling, rough milling, sawing, deburring, molding process, waste recycling technology

Rubber, leather, plastic Shoe

making, tire rim renovation, plastic processing, film production, extrusion, model production, textile production

Rubber, leather, plastic Shoe

making, tire rim renovation, plastic processing, film production, extrusion, model production, textile production

Fiber fluff textile dustPolishing,

paper machines, waste separation, textile processing, food processing, waste recovery devices, insulation material production, asbestos cleaning

Fiber fluff textile dustPolishing,

paper machines, waste separation, textile processing, food processing, waste recovery devices, insulation material production, asbestos cleaning

Sticky dustPharmaceutical industry,

food, animal feed, paint, plastic products, mold production. Production of printing presses, tires, chips, ceramic coatings, adhesives, textile finishing, mixing, and conveying devices

Sticky dustPharmaceutical industry,

food, animal feed, paint, plastic products, mold production. Production of printing presses, tires, chips, ceramic coatings, adhesives, textile finishing, mixing, and conveying devices

Residual gas containing Large

kitchen, animal carcass processing equipment, food processing, cleaning equipment, mixing station, biological filtration equipment, drug degreasing device, animal variety improvement

Residual gas containing Large

kitchen, animal carcass processing equipment, food processing, cleaning equipment, mixing station, biological filtration equipment, drug degreasing device, animal variety improvement

Flammable and explosive Polishing

process, post process polishing, jet machines, explosive production, waste recovery and drying devices, grain processing, printed circuit board production, brake detection devices, power plant technology, minerals.

Flammable and explosive Polishing

process, post process polishing, jet machines, explosive production, waste recovery and drying devices, grain processing, printed circuit board production, brake detection devices, power plant technology, minerals.

Carbon ashBentonite filler, carbon

black mixer, tire production, cement industry, minerals, electrode production, mold production, paint production

Carbon ashBentonite filler, carbon

black mixer, tire production, cement industry, minerals, electrode production, mold production, paint production

1. Mixture of centrifugal fan and dust collector

2. Mixing of water with dynamic sedimentation and rolling waves

3. Low water consumption

4. Continuous operation

5. Air volume unchanged

6. The collected dust is discharged in the form of mud

7. Steel hard

8. With pretreatment device

9. Cooling exhaust gas

10. Can be paired with a pre filtration system

11. Suitable for high-temperature, humid, flammable and explosive smoke and dust

1. Small footprint and low installation costs

2. Air flow rate changes but efficiency remains unchanged

3. Low operating costs

4. Continuous operation without interruption or re commissioning

5. Appropriate wind speeds do not require a margin factor

6. No secondary dust problem

7. Stable operation and long service life

8. Handling high concentration and low maintenance costs

9. May cause moisture to condense

10. Capable of handling high concentration dust laden air streams

11. Solve security hazards and use them in multiple fields