1. The EHRCN-D self-excited dust collector is a wet dust collector that uses water as the washing solution. It uses the pressure head of the induced draft fan to guide the airflow to excite vortices, wash with waves, and purify smoke and dust.

2. According to the principles of aerodynamics, when dusty gas enters the dust collector from the inlet, the airflow turns downward and impacts the larger dust particles on the water surface, which fall into the water. When the dusty gas passes through the"S" type special airflow mechanism at a speed of 18-35 meters/second, it accelerates and triggers a large number of continuous and violent waves, which impact or excite the washing dust, allowing the water vapor to fully contact the dust and be envelopedby water mist, causing volume expansion and sinking into the water, allowing the dusty gas to be fully purified.

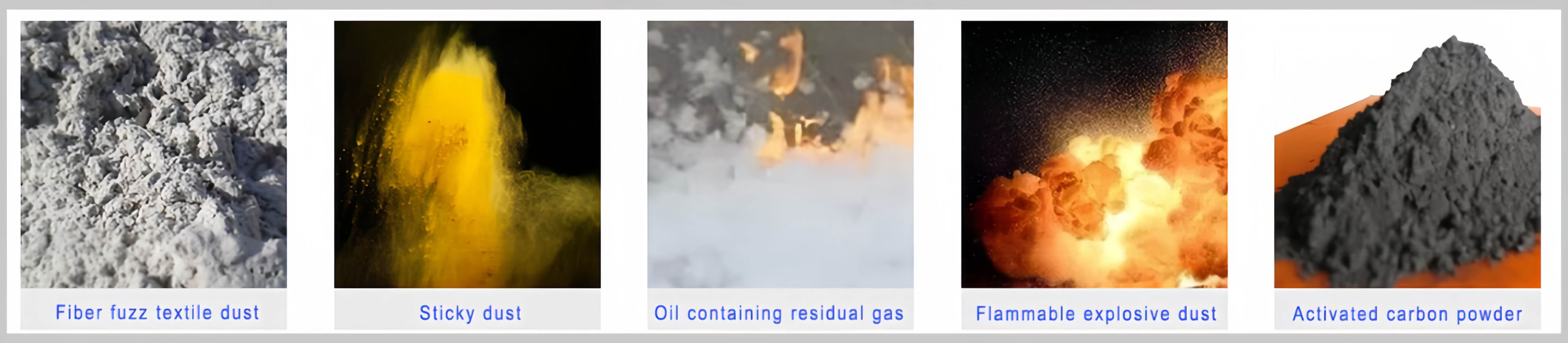

3. EHRCN type wet dust collector is often used for various types of smoke and dust that are difficult to solve, such as high temperature, oil and water content, flammable and explosive, adhesive, and cannot be solved by traditional filter material dustcollectors.

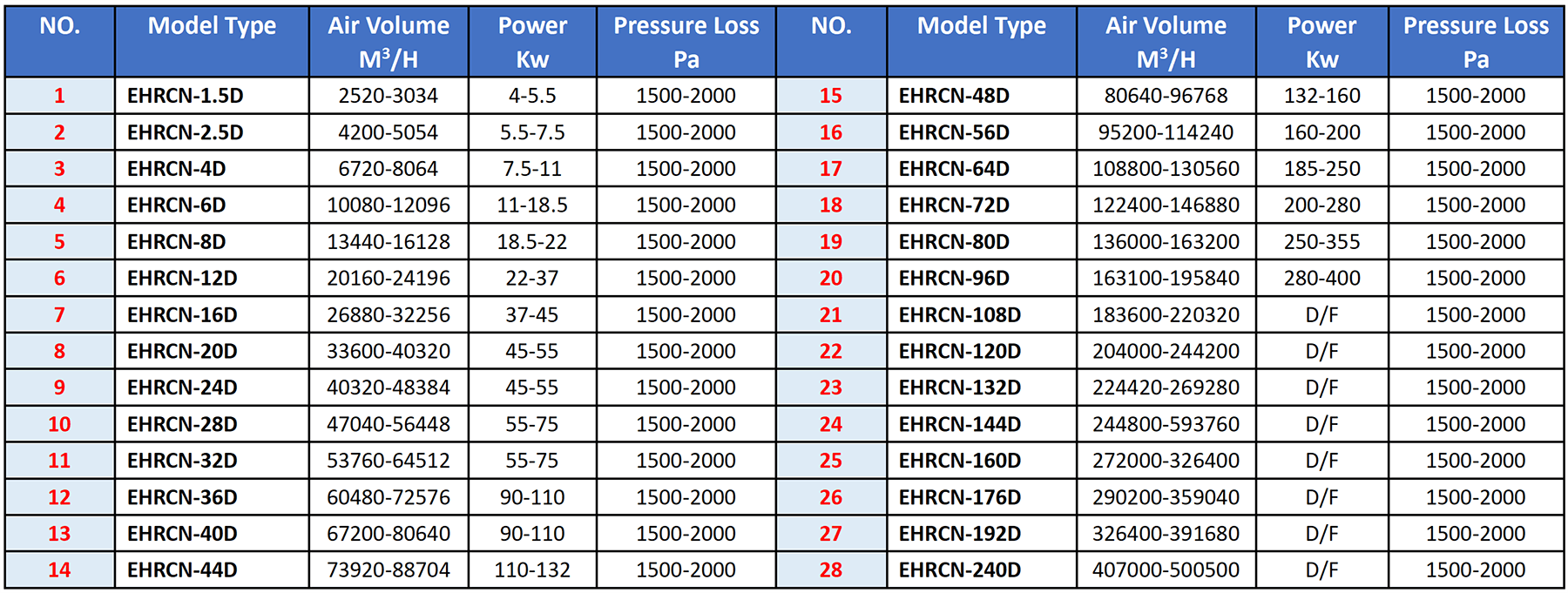

1.1 Product Name: RCN-D Wet Dust Collector (Air Volume: 2500-50000 cubic meters/hour)

1.2 Sludge treatment method: A pyramid shaped conical bucket is used to discharge the sludge to the pipeline system through downward impact.

1.3 Appearance features: It can be continuously or simply cut for slag flushing, and can be automatically controlled by PLC.

1.4 Equipment Material: Carbon steel anti-corrosion, SUS304 stainless steel, 316L stainless steel can be selected.

1.5 Core components: Wave maker, liquid level control water tank, at least SUS304 stainless steel material should be selected.

1.6 Product principle: Utilizing the pressure head of the fan, it triggers a violent rolling water mist, creates waves, washes and purifies dust.

1.7 Unilateral impeller: RCN-6D models (including 6D) and below are single turbine wave generators.

1.8 Double sided impeller blades: RCN-8D models (including 8D) and above are twin turbine wave generators.

1.9 Applicability: Sintering, slag blocking, and rod grinding in steel vanadium plants; Material transportation, crushing, and screening in chemical or quarrying industries.

1.10 Advantages: No need for water pumps, no need for sprinkler heads, no fear of blockage, small footprint, high dust removal efficiency.

Ore crushing

Activated carbon fiber dust

Alkaline quartz powder

Metal polishing dust

Keywords: wet dust collector

Phone